Already proven across stadia and major sporting events throughout Australia, Europe and the United Kingdom, The WISE solution is that game changer via:

What happens to your cup once you’ve returned to bar or donated to charity?

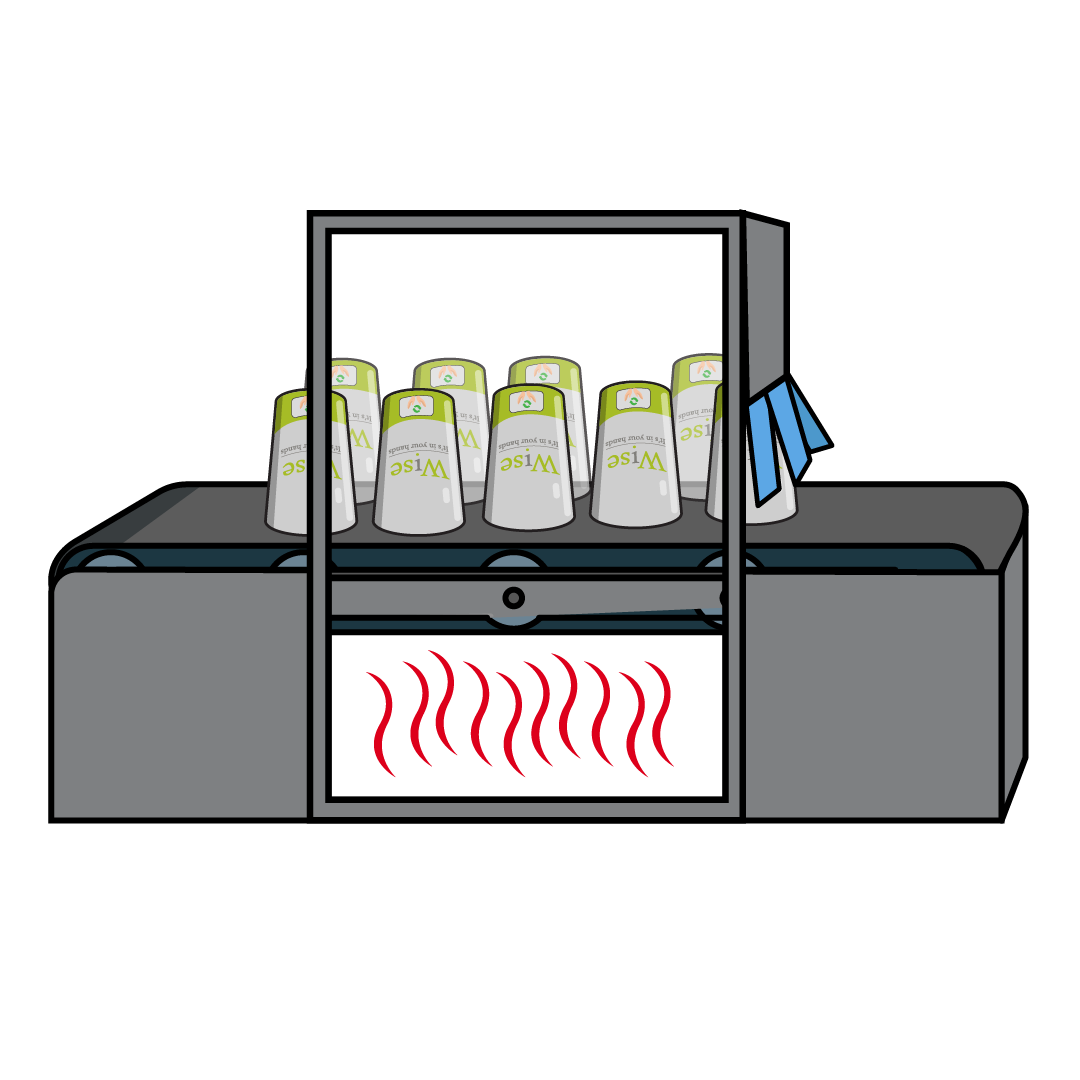

Our game changing machine is capable of the complete sanitization of 10,000 of our cups per hour, whilst consuming only 92 litres of water in doing so. This is the WISE point of difference, none of our competitors have this capability as standard dishwashers do not sanitise or dry the cups sufficiently.

Our first state-of-the-art purpose-built wash plant was the culmination of two years research and development work. WISE worked specifically on the design and manufacture of the WISE washing machine focussing on the needs of the industry to develop a complete closed loop process to wash, sanitize, certify and return clean cups to venues.

The WISE wash plant is HACCP certified to offer peace of mind that all cups are compliant for the beverage service industry, including periodic bacterial testing consistent with industry standards.To manage this process involves employing local crew to operate and run the wash plant, thus creating and maintaining positions within the Australian Economy. No secrets here! For more reading and specs on the wash process, click the the link below.